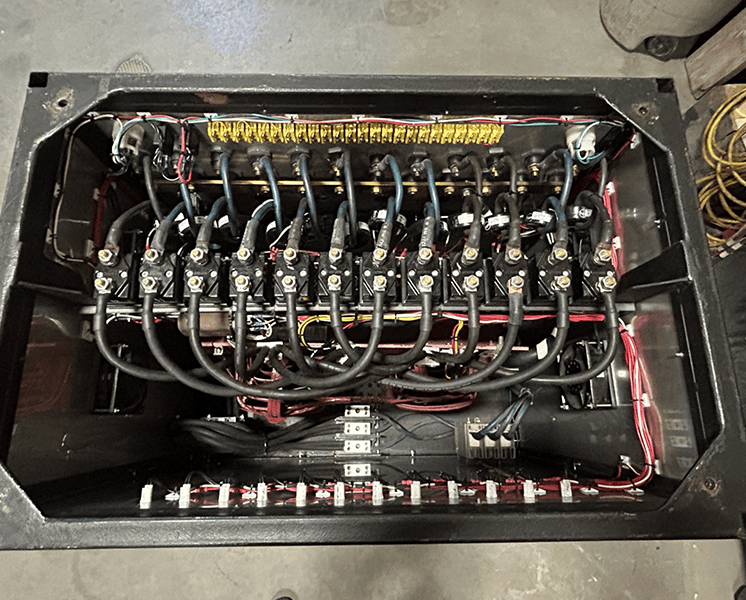

At Techeat, we pride ourselves on delivering exceptional heat treatment services through cutting-edge Electrical Resistance technology.

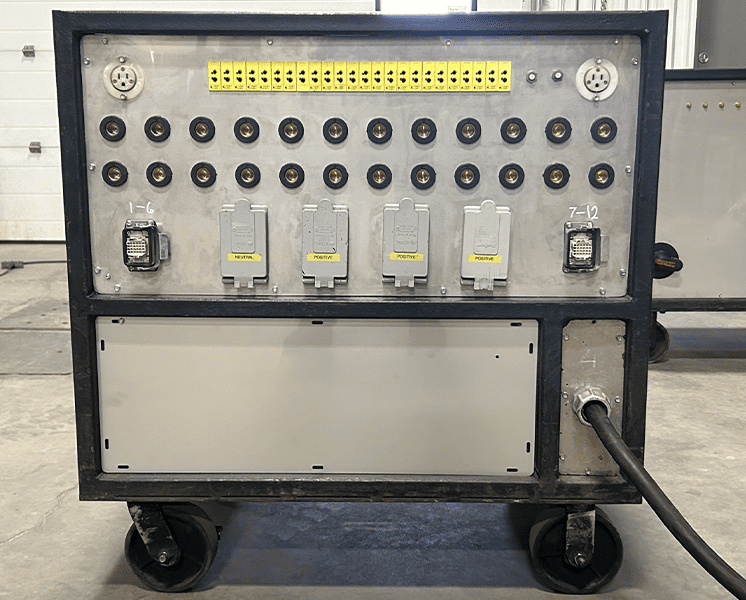

Our proprietary consoles enable us to provide a distinct advantage, energizing twice the number of control zones compared to the industry standard. With our top-of-the-line equipment and unmatched expertise, we guarantee to impress and satisfy, offering you the best value in the industry.

Our range of services encompass various applications, including:

PWHT:

Our Electrical Resistance technology ensures precise and controlled heat treatment after welding, enhancing the structural integrity of your components.

Welding Preheat:

Experience controlled and efficient preheating of weld joints, minimizing potential cracking and ensuring superior weld quality.

Hydrogen Bake-out:

Eliminate hydrogen-induced defects through our thorough bakeout process, enhancing the quality and longevity of your equipment.

Coating Cures:

Achieve optimal coating performance with our precise curing solutions, ensuring the longevity and effectiveness of protective coatings.

Annealing and Normalizing:

Our Electrical Resistance technology facilitates controlled annealing and normalizing, enhancing material properties while reducing residual stresses.

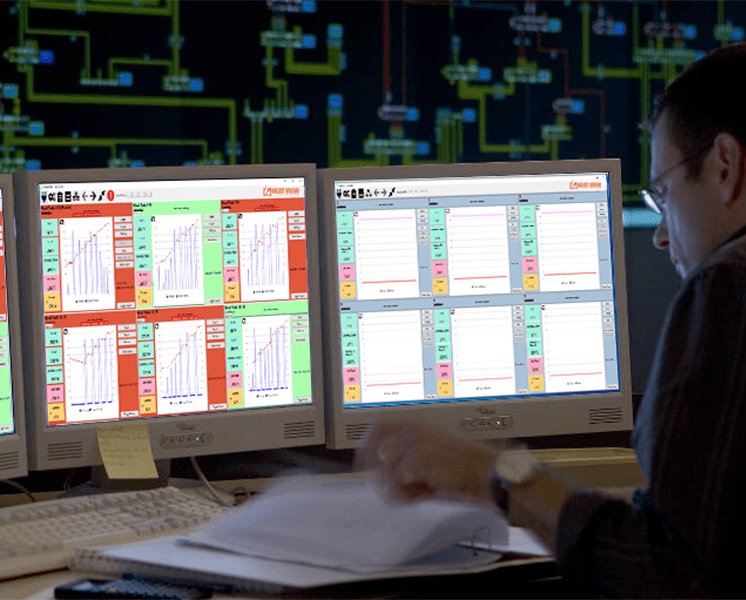

Wireless Heat Treating:

On-Site control rooms with TECLINK™ software, and Certified Heat Treatment Technicians ensure the ability to remotely control heat cycles without costly delays, and safety issues due to off-site IT people. Effortlessly control heating cycles, log temperature data, and generate comprehensive PDF reports, and remotely operate your projects.

Line Thawing:

Our advanced approach swiftly and safely thaws frozen lines, reducing downtime and maintaining operational continuity.

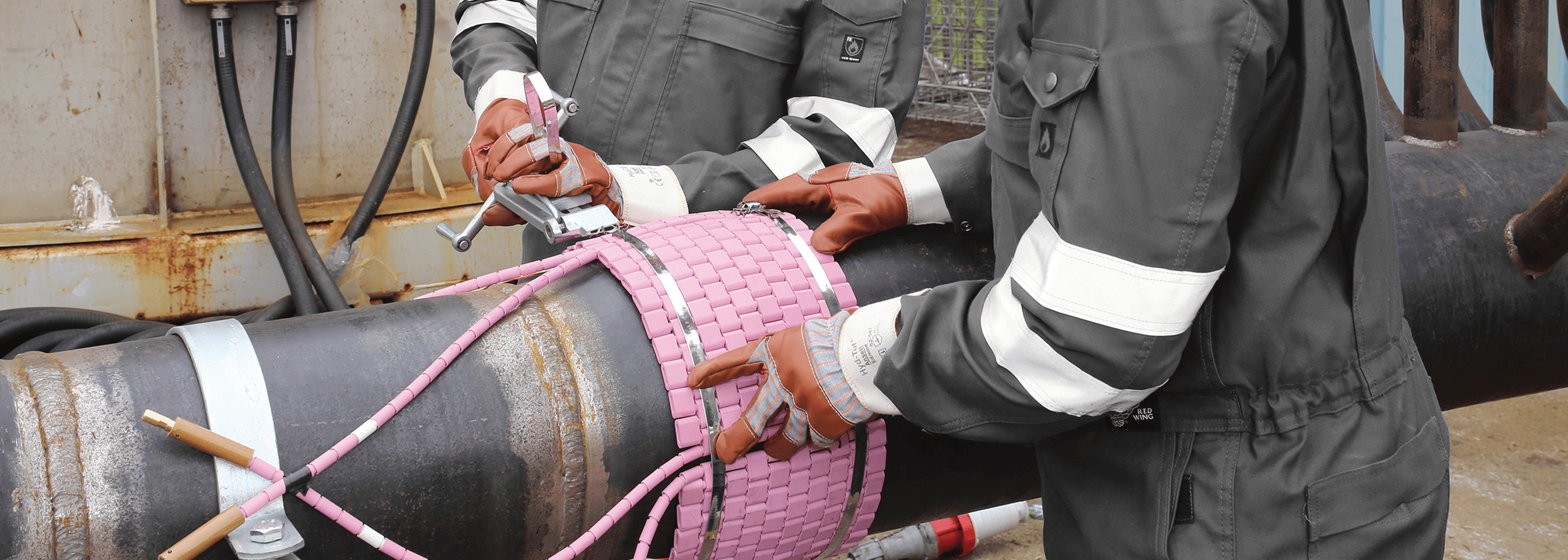

CooperCoil™ :

Techeat’s CooperCoil™ is a next-generation 40/80V braided heating element, purpose-built for the most demanding welding environments. Its low-profile, ultra-flexible design allows seamless integration into tight spaces and irregular geometries, without obstructing the weld. Unlike bulkier heating systems, CooperCoil™ is designed to work with the welder, not against them, improving visibility, access, and control where it matters most.

TechMat™ :

Commonly known in the field as the “Magnetic Pads”, TechMat™ is Techeat’s innovative response to one of the most time-consuming steps in heat treatment: pin welding.

Designed to eliminate the need for traditional stud welding on shell surfaces, TechMat has reduced pin usage by over 95%, freeing up your Boilermakers and drastically reducing post-WOL cleanup and NDE involvement

The result? Less rework, lower costs, and faster turnaround.

With Techeat’s Electrical Resistance technology, you gain access to unmatched control and precision in heat treatment processes. Our commitment to innovation, combined with our comprehensive range of services, guarantees exceptional results that meet and exceed industry standards.

Experience the next level of heat treatment with Techeat – where excellence is powered by Electrical Resistance.